Introduction to Automatic Powder Coating Machine

An automatic powder coating machine is an advanced industrial device engineered to uniformly apply dry powder coatings onto a diverse range of surfaces. It typically comprises four key components: a powder feeder, which is responsible for accurately supplying the powder material; a spray gun, designed to precisely spray the powder onto the target object; a sophisticated control system, capable of managing and optimizing the entire coating process; and a curing oven, used to harden the powder coating through heat treatment, ensuring a durable and high - quality finish.

Application Scenarios

These machines have found extensive applications across multiple industries. In the automotive industry, they are used to coat car bodies, wheels, and interior components, enhancing both the aesthetics and corrosion resistance. In the furniture industry, automatic powder coating machines are employed to finish wooden and metal furniture surfaces, providing a smooth and long - lasting appearance. In the construction industry, they play a crucial role in coating metal structures such as bridges, fences, and building facades, protecting them from environmental degradation.

Equipment Price

The cost of an

automatic powder coating machine can vary significantly. Basic models, suitable for small - scale production or hobbyist use, may start at a few thousand dollars. On the other hand, high - end, large - scale industrial machines, equipped with advanced features like multi - color spraying capabilities and high - speed production capacity, can cost over tens of thousands of dollars. The price is mainly determined by factors such as the machine's size, functionality, brand reputation, and the level of automation.

Correct Usage

Proper operation of the

automatic powder coating machine is essential for achieving optimal results. First, the workpiece must be thoroughly prepared by cleaning and degreasing to ensure good adhesion of the powder coating. Next, carefully adjust the machine's parameters, including powder flow rate and air pressure, according to the type of powder and the desired coating thickness. Then, start the spraying process, moving the spray gun evenly across the workpiece to achieve a uniform coating. Finally, transfer the coated workpiece to the curing oven, setting the appropriate temperature and time based on the powder's specifications.

How to Choose

Selecting the right

automatic powder coating machine requires careful consideration. First, assess your production volume requirements. If you have high - volume production needs, a high - speed, automated machine may be more suitable. Also, consider the type of powder you will be using, as different powders may require specific machine settings. The size and shape of the workpieces are also important factors, as they will determine the size and configuration of the machine. Additionally, research the reputation of the manufacturer and the quality of their after - sales service, as reliable support can be crucial for the long - term operation of the machine.

Safety Precautions

Safety should always be a top priority when operating an automatic powder coating machine. Always wear appropriate protective gear, including masks to prevent inhalation of powder particles, and gloves to protect your hands. Ensure that the working area is well - ventilated to minimize the risk of powder accumulation in the air. It is also essential to properly ground the machine to prevent electric shock hazards. Regularly inspect the machine for any signs of wear or damage to ensure safe operation.

Rationality Analysis

automatic powder coating machines offer several advantages that make them a rational choice for many industries. Their high - efficiency operation significantly reduces labor costs, as they can complete the coating process much faster than manual methods. Moreover, they improve coating quality by ensuring consistent and uniform application. The high transfer efficiency of these machines also minimizes powder waste, making them more cost - effective in the long run.

Q&A

Q1: What is the lifespan of an automatic powder coating machine?

A: With regular maintenance, including cleaning, part replacement when necessary, and proper storage, an automatic powder coating machine can have a lifespan of 5 - 10 years.

Q2: Can it handle different colors of powder?

A: Yes, most automatic powder coating machines are capable of handling multiple colors. However, it is crucial to thoroughly clean the powder feeder, spray gun, and other components between color changes to avoid color contamination.

Q3: Is it difficult to operate?

A: While the operation of an automatic powder coating machine may seem complex at first, with proper training provided by the manufacturer or a professional, operators can quickly become proficient in its use.

Q4: How to maintain the machine?

A: Regular maintenance involves cleaning the powder feeder and spray gun after each use to prevent powder buildup. Periodically check the wear of parts such as nozzles and filters, and replace them when necessary. Also, ensure that all electrical and mechanical components are in good working condition.

Q5: What if the coating thickness is not uniform?

A: If the coating thickness is uneven, first check the spray gun's distance from the workpiece; it should be kept consistent. Adjust the spray gun's angle to ensure even coverage. Additionally, verify the powder flow rate settings and make adjustments if needed.

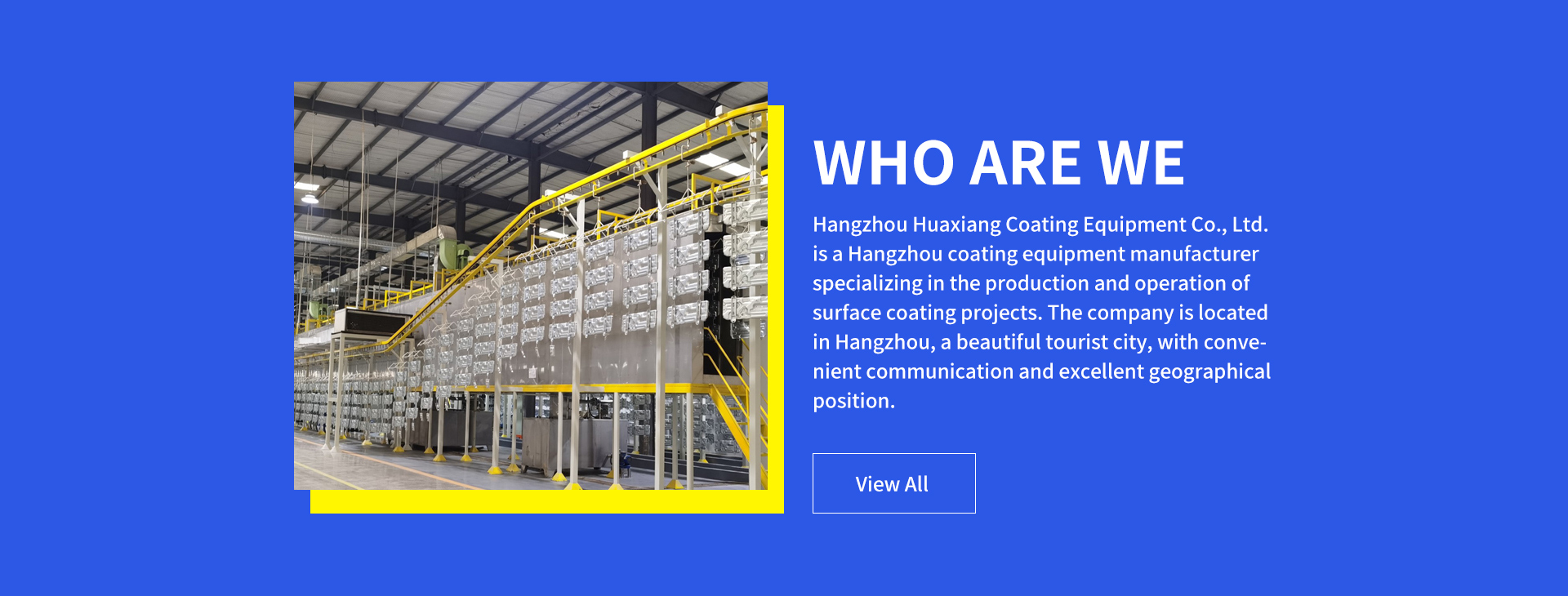

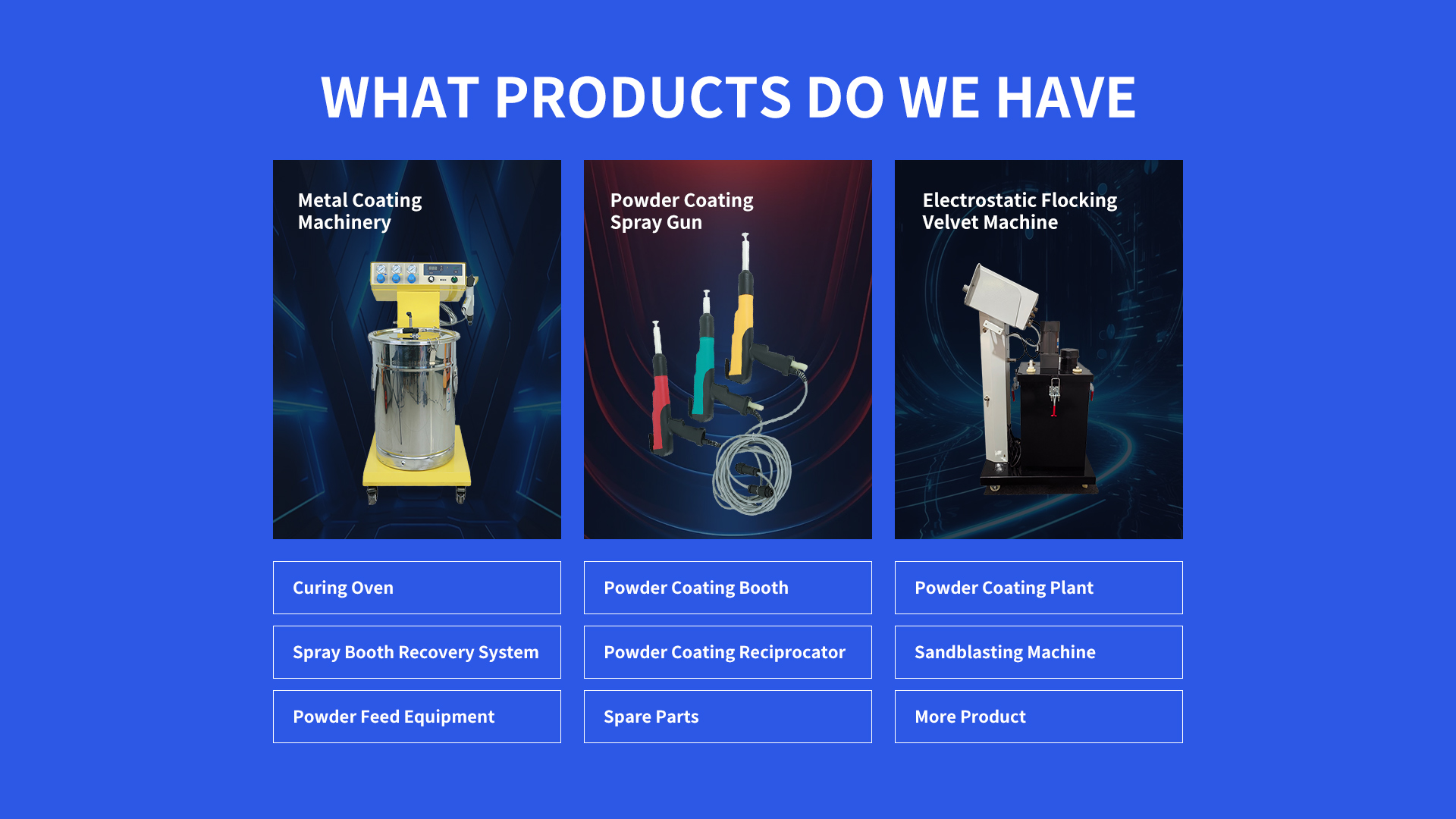

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com